A GUIDE compiled for a visit by the board to Blackburn’s ROF factory in 1957 provides us with a fascinating glimpse inside the secret world of what was once one of Blackburn’s largest employers.

The booklet features a number of great photos of the various departments and processes which were undertaken at the factory off Roman Road.

Former ROF employee Michael Albin shared the booklet with Looking Back.Michael started work with the Royal Ordinance Factory as an apprentice in 1975 and work there until it closed in 2002.

The presentation booklet - marked ‘secret’ on the front cover - was published for a visit by board members on June 24, 1957.

The dignitaries were given a tour of the factory which produced fuses and arming mechanisms for shells and later missiles which were used in conflicts around the world.

They were informed that the site was so large - 33 acres - that they would not be able to visit every department.

At the time of the visit, ROF employed 1,874 people (including its own police force of 15).

During the Second World War over 5,000 worked at ROF.

The brochure gives a fascinating snippet into life at ROF immediately after the war reporting that beyween 1946 and 1948 the factory produced over one million alarm clock movements before production once again switched back to the large-scale manufacture of mechanical fuses.

Women were a key to the factory’s prodigious output. During the war around 3,500 women worked there producing 15,000 fuses every week, working 50-hour weeks. Even by 1957, the workforce was predominantly female with over 700 of them on the production lines and more than 250 involved in inspecting completed orders.

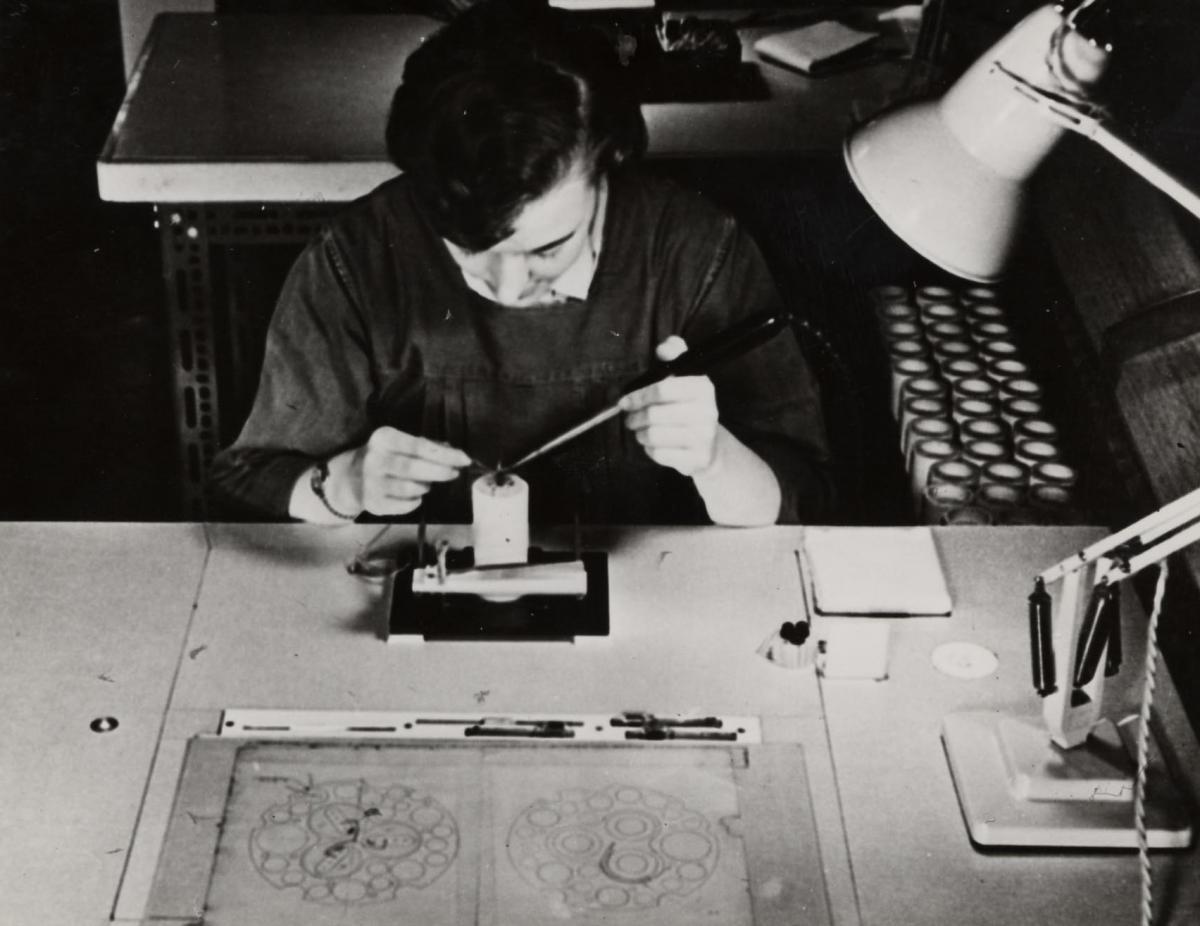

The photos show the factory to be a combination of heavy industrial processes and delicate, precision engineering with row upon row of desks, each with their own task lighting as more and more electronics were introduced into the manufacturing process.

The quality of ROF’s work was renowned with the mechanisms being produced to tolerances of less than a thousandth of an inch.

The board were told that major changes had taken place between 1951 to 55 with an expansion and modernisation programme increasing production capacity by 50 per cent.

Comments: Our rules

We want our comments to be a lively and valuable part of our community - a place where readers can debate and engage with the most important local issues. The ability to comment on our stories is a privilege, not a right, however, and that privilege may be withdrawn if it is abused or misused.

Please report any comments that break our rules.

Read the rules hereLast Updated:

Report this comment Cancel